Efficiency and quickness are not only desirable qualities in today’s dynamic market; they are necessary. Businesses of all sizes are searching for more efficient and cost-effective methods to move goods. Cross docking can help with it. This ingenious strategy helps businesses satisfy expanding customer demands while reducing costs. It changes how products are handled, putting more emphasis on quick, direct distribution than on long-term storage.

What Is Cross Docking?

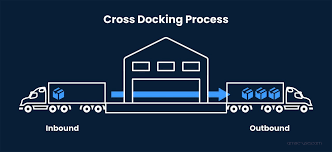

Cross docking is a simple but powerful logistics method. It involves taking goods from incoming trucks and moving them straight onto outgoing trucks—with little to no storage in between. Instead of sitting in a warehouse for days, products stop at a cross docking terminal for only a few hours. They are sorted there before being promptly dispatched once more.

Imagine it as a crowded train station. Without spending too much time in one location, packages arrive, are sorted, and then are shipped out again. Time, space, and additional handling are reduced by this method.

How Does It Work?

Here’s a quick look at the typical cross docking process:

Goods arrive at the terminal from different suppliers.

Items are sorted based on where they need to go.

If needed, products from different suppliers are combined into one shipment.

Then they are loaded onto outbound trucks and sent off.

This system needs good timing and strong coordination. But when done right, it works like a well-oiled machine.

Why More Companies Use Cross Docking

More and more businesses are turning to cross docking—and for good reason. Here are the main benefits:

1. Faster Deliveries

Products travel through the supply chain considerably more quickly when there are no storage delays. This enables businesses to fulfill their promises of quick deliveries and satisfied clients.

2. Lower Storage Costs

Costs associated with long-term storage, lighting, and additional manpower are eliminated since commodities are not kept in a warehouse.

3. Less Inventory Risk

There is less possibility of spoiling, loss, or damage when there are fewer things in stock. When used with just-in-time inventory systems, cross docking performs admirably.

4. Fewer Touchpoints

There is less possibility of spoiling, loss, or damage when there are fewer things in stock. When used with just-in-time inventory systems, cross docking performs admirably.

When Is Cross Docking the Right Choice?

Cross docking isn’t right for every situation. It works best when:

Products are pre-labeled and ready to ship.

There’s steady demand and large order volumes.

Your tracking and transportation system is nicely thought out.

Your company provides services to e-commerce sites, logistics hubs, and large retailers.

In order to move items effectively and safely, cross docking is widely utilized in sectors including supermarkets, retail, auto parts, and healthcare.

Final Thoughts

Businesses want better solutions as supply chains become more complicated and customer demands rise. Among those solutions is cross docking. It expedites the distribution of products and eliminates time-consuming, expensive stages. Cross docking provides a quicker, more efficient method of moving goods for companies looking to maintain their competitiveness. It is the wise course of action, not simply a fad.